Polypropylene (PP) is widely used in the plastics industry due to its diverse and excellent properties. It can be found in applications ranging from everyday items to industrial components. The variety of processing methods is key to its extensive application.

With technological advancements, more innovative processing methods continue to emerge, expanding the application scope of polypropylene. Next, we will continue to explore other important polypropylene processing methods and how they further enrich the application of polypropylene.

How to select polypropylene based on material properties and product requirements?

Polypropylene comes in a wide variety, and different grades and modification methods endow it with diverse properties. Therefore, a wise selection not only optimizes production efficiency but also ensures that the final product meets the expected functional and quality standards.

- Melt Flow Index (MFI): The melt flow index determines the fluidity of polypropylene, affecting its processability and product suitability.

- Crystallinity: Crystallinity influences the hardness, stiffness, and heat resistance of polypropylene, determining its performance in different temperature environments.

- Copolymer Type: Different types of copolymers provide polypropylene with varying flexibility and impact resistance, catering to the needs of different application fields.

- Additives: Additives can enhance the antioxidant, UV-resistant, and flame-retardant properties of polypropylene, extending the product’s service life.

What factors affect the quality and performance of the final product?

From raw material selection to the final processing stage, every step can influence the quality and performance of polypropylene products. Understanding these key factors helps us better control product quality and meet diverse application requirements.

- Raw Material Purity: The purity of raw materials directly affects product quality; impurities can lead to defects.

- Temperature Control: Processing temperature impacts the fluidity and crystallinity of polypropylene, and improper temperature can cause product deformation.

- Pressure Control: Pressure control ensures complete filling and dimensional accuracy of the product.

- Cooling Rate: The cooling rate affects the crystallinity and mechanical properties of polypropylene.

What are the differences in the application fields of polypropylene products?

Due to its diverse processing methods and customizable properties, polypropylene exhibits significant differences in various application fields. Understanding these differences helps us better leverage the potential of polypropylene to meet the needs of different industries.

- Food Packaging: Polypropylene is widely used in food packaging due to its chemical resistance and moisture barrier properties, requiring it to meet strict food safety standards.

- Consumer Goods Packaging: In consumer goods packaging, polypropylene needs to possess excellent chemical resistance and impact strength.

- Automotive Components: The automotive industry demands polypropylene products with high strength, heat resistance, and weather resistance.

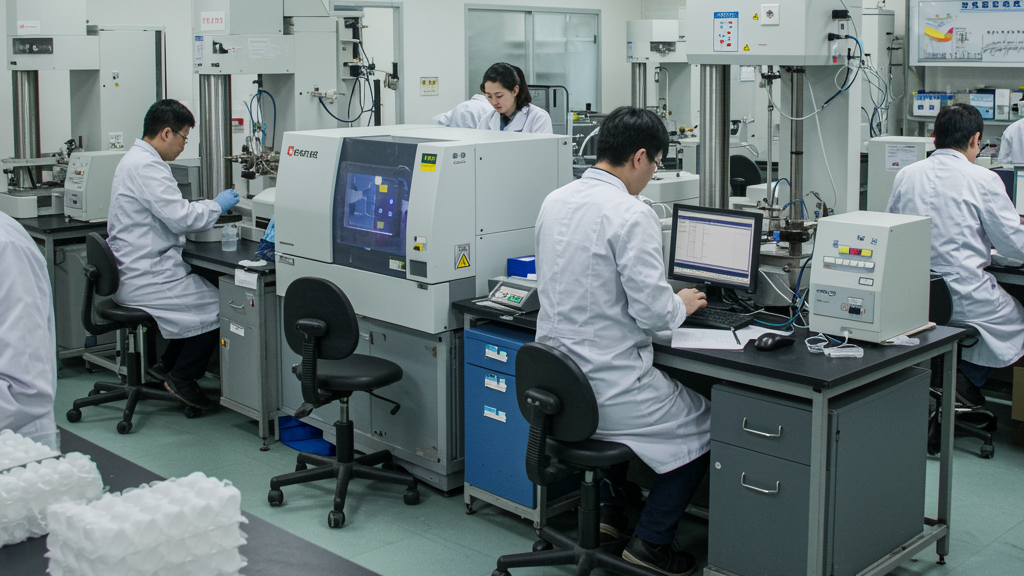

- Medical Devices: The medical field has extremely stringent requirements for the biocompatibility and sterilization capabilities of polypropylene products.

Application of polypropylene in different fields

|

Application Area |

Application Examples |

Performance Requirements |

| Packaging | Food containers, beverage bottles | Non-toxic, moisture-resistant, chemical-resistant |

| Automotive | Car interiors, bumpers | High strength, heat resistance, impact resistance |

| Medical | Syringes, medical packaging | Biocompatibility, sterilizability |

| Home Appliances | Appliance housings, internal parts | Heat resistance, flame retardancy, good appearance |

Innovations and Development Trends in Polypropylene Processing Technology

The innovations and development trends in polypropylene processing technology are mainly reflected in four aspects: sustainability, precision processing, high-performance materials, and intelligent automation.

1.Sustainability and Environmental Protection: Focus on the development of recyclable and biodegradable polypropylene to reduce environmental pollution.

2.Precision Processing Technology: Micro-injection molding and 3D printing technologies are driving the application of polypropylene in the medical and electronics industries.

3.High-Performance Materials: Research and development of modified polypropylene and composite materials enhance the mechanical properties and application scope of polypropylene.

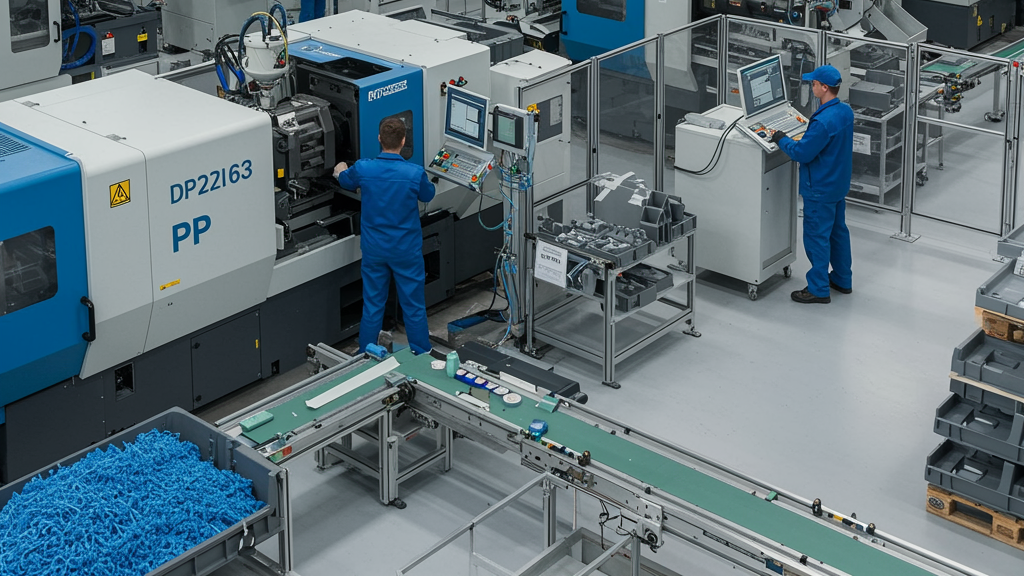

4.Intelligent and Automated Systems: Automated production lines and intelligent control systems improve production efficiency and product quality.

Conclusion

Polypropylene processing technology is advancing towards sustainability, precision, high performance, and intelligence. These innovations enhance production efficiency, optimize product quality, and enable polypropylene to play an increasingly vital role in modern industry.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Mar-24-2025